CN

Home

About Us

About Us

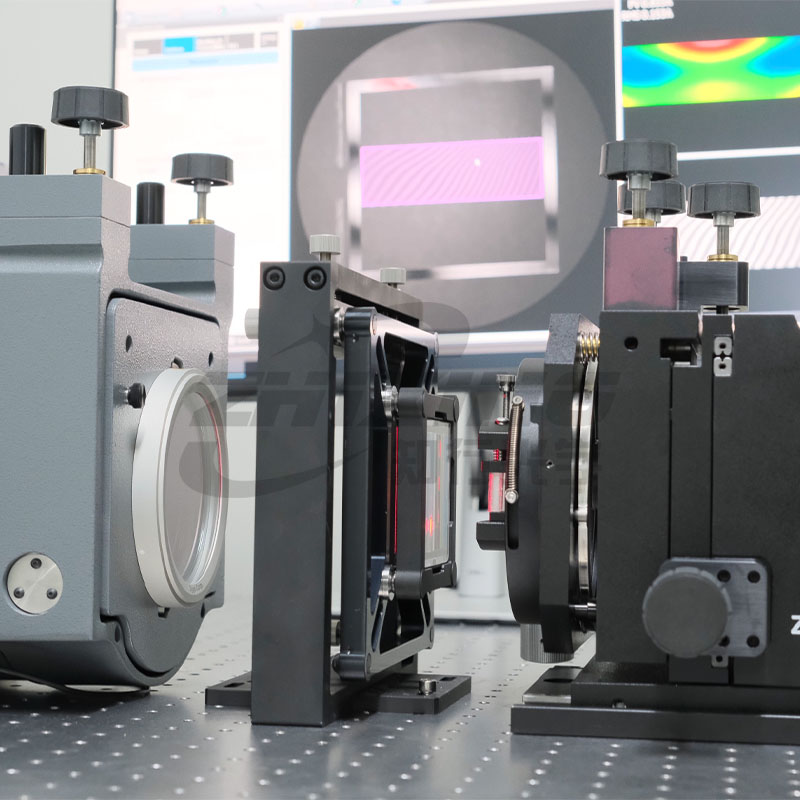

Ningbo Zhixing Optical Technology Co., Ltd. is a technology-based enterprise specializing in the research and development of optical devices

Products

Products

Ningbo Zhixing Optical Technology Co., Ltd. is a technology-based enterprise specializing in the research and development of optical devices

Contact Us

Contact Us

Ningbo Zhixing Optical Technology Co., Ltd. is a technology-based enterprise specializing in the research and development of optical devices